Automatic Generator Bearing Re-Greasing System (AGRGS)

Precise, Fully Automated

The Automatic Generator Bearing Re-Greasing System (AGRGS) prevents inadequate lubrication and reduces costs and workload.

- Precise, continuous lubrication, without manual overhead

- Reduced costs and workload

- Enhanced safety for human and machine

Automatic Generator Bearing Re-Greasing System (AGRGS)

Automatic, Continuous Lubrication to Minimize Workload and Costs

- Precise, continuous lubrication

- Even distribution of the bearing temperatures

- Reduced costs and effort

- Maintenance-friendly system

- Enhanced safety for human and machine

- Designed according to the long-term field experience

On this page

AGRGS components

What does MWM AGRGS offer users?

Technical benefits

Requirements for your AGRGS kit

The Automatic Generator Bearing Re-Greasing System (AGRGS) is a standalone lubrication system for generators bearings, that provides continuous automatic lubrication and remove requirement for manual greasing during service intervals. The main objective of the system is to prevent non adequate lubrication and to optimize service costs. As a result, the corresponding equipment lifetime is extended and the associated travel and labor costs are reduced, accordingly. The system is applicable to all Marelli generators with grease class NLGI-2 or higher. It can be used in both the 50 Hz and 60 Hz models.

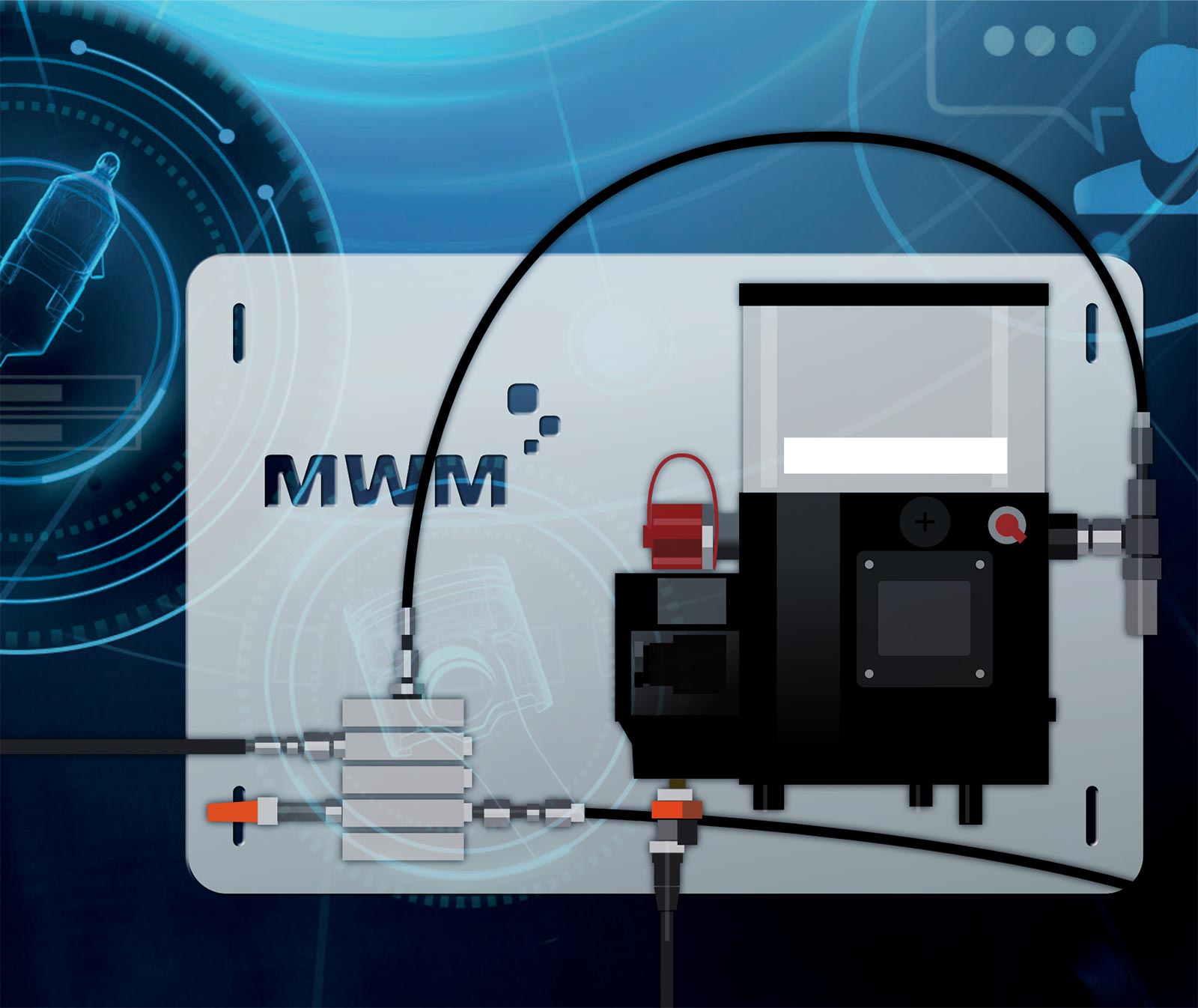

The Automatic Generator Bearing Re-Greasing System consists of the following components:

- Piston pump with tank and high-pressure hoses

- Distributor (ratio: 1:1, 1:2, 1:3)

- Mounting plate

- Electrical components for TEM/TPEM connection

- Filling tool (optional)

- Mounting material including bracket (optional)

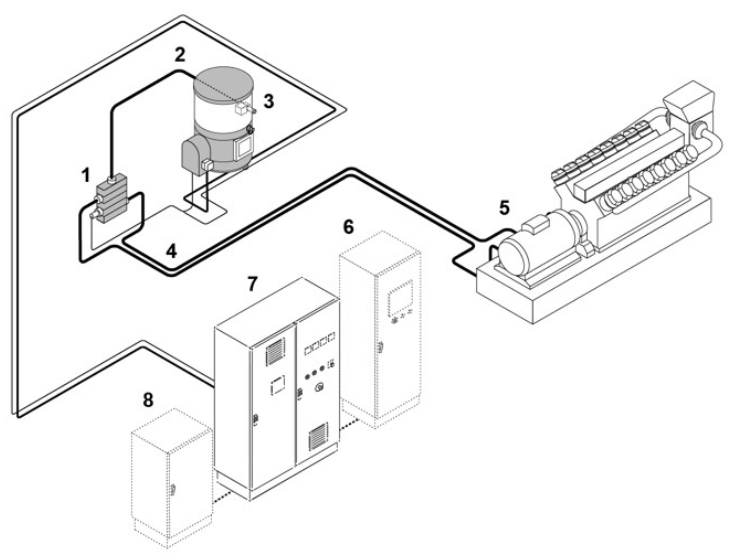

The piston pump (3) presses lubricant into the main line (2) which is connected to the distributor (1). Within the distributor, the grease is directed to the generator bearings according to the selected distributor ratio. The lubricator reaches the generator bearings (5) through the lubrication lines (4). Electrical power is supplied to the piston pump by the auxiliary equipment cabinet (HAS) (7). HAS is also assuring connection between AGRGS and the plant control system (both TEM and TPEM).

What does MWM AGRGS offer users?

The Automatic Generator Bearing Re-Greasing System ensures regular and precise lubrication with reduced costs due to an automatic process. Non-adequate lubrication can, in the worst case, lead to bearing damage, which in turn causes unplanned costs and unscheduled downtimes.

Technical benefits:

- Precise, continuous lubrication, without manual overhead

- Reduced costs and workload

- Maintenance-friendly system

- More even distribution of the bearing temperatures

- Enhanced safety for human and machine

- Use of a proven system

Requirements for your AGRGS kit:

The information must be read from the generator type plate in order to ensure correct system configuration.

For further information, please contact your MWM service partner.

Order your AGRGS kit directly in the Service Shop or contact your responsible service partner.

For general inquiries about service products, please contact serviceproducts@mwm.net.

Gasmotoren & Produkte

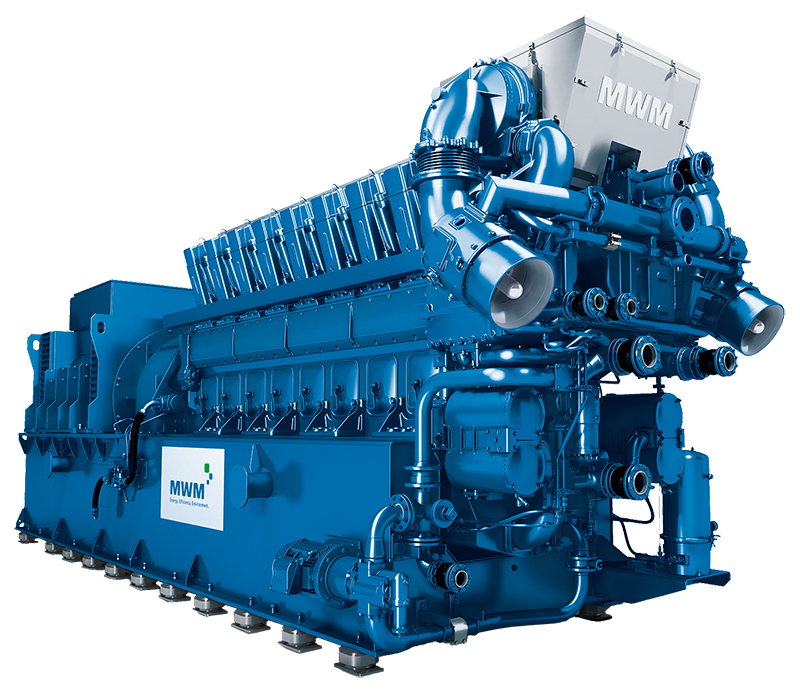

Gas Engine TCG 3016

New development – greatly reduced operating and installation costs and fully digitized power plant control.

Gas Engine TCG 2020

Best electrical and thermal efficiency in its class. All gas types: natural gas, biogas, mine gas, landfill gas, sewage gas.

Gas Engine TCG 2032

High reliability. Low operating costs. Gas types: natural gas, landfill gas, sewage gas, mine gas, coke oven gas. Mainly used in large IPP projects with up to 100 MWel.

Cogeneration Power Plant Solutions

Eco-friendly MWM cogeneration power plants with combined heat and power enable decentralized, economical and energy-efficient power production.

Container Cogeneration Plant

Compact modules for the TCG 3016, TCG 3020 and 2020 gas engines. Complete turnkey systems for special applications.

Contact Service

Caterpillar Energy Solutions GmbH Carl-Benz-Strasse 1 68167 Mannheim Germany

T +49 6 21/3 84 – 0 F +49 6 21/3 84 – 88 00 E service@mwm.net