The REMISBIO research project develops catalysts and tests them in CHP biogas plants in order to reduce methane emissions and increase the energy efficiency of gas engines

Mannheim, June 29, 2016

Together with the German Biomass Research Centre (DBFZ) and the Hanau-based technology group Heraeus, Caterpillar Energy Solutions is currently working on an innovative concept for the reduction of emissions from CHP biogas plants. A jury selected the REMISBIO project from 600 submissions for participation in the “Environment Week”, during which it presented itself in the park of Bellevue Palace on June 7 and 8.

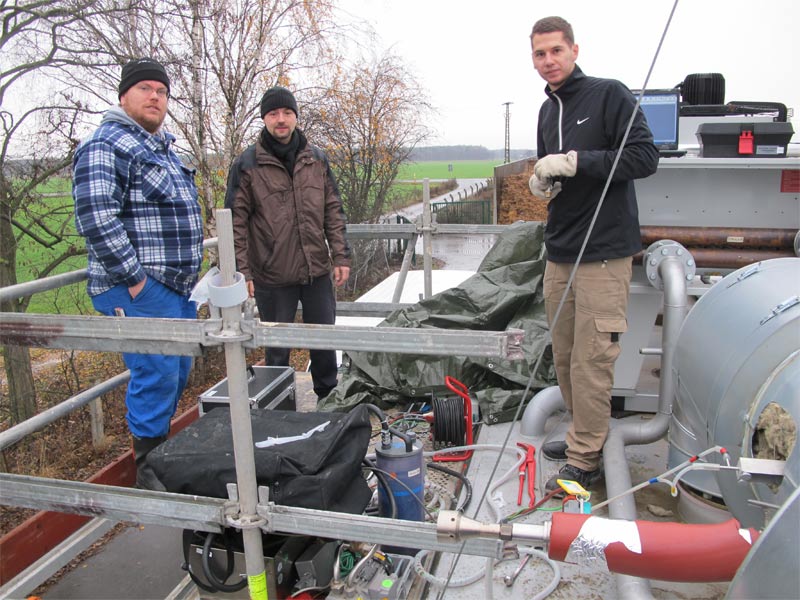

Heinrich Baas of Caterpillar Energy Solutions, Dr. Ingo Hartmann of DBFZ, and Dr. Christian Breuer of Heraeus in front of the mobile test system (from left to right)

Heinrich Baas of Caterpillar Energy Solutions, Dr. Ingo Hartmann of DBFZ, and Dr. Christian Breuer of Heraeus in front of the mobile test system (from left to right)

Heinrich Baas, Head of Plant Predevelopment at Caterpillar Energy Solutions, was on site to answer the questions of event visitors. “As a leading manufacturer of eco-friendly gas engines and power generators for distributed energy supply, we wanted to make a key contribution to the research conducted for the purpose of reducing emissions. MWM’s product portfolio comprises gas engines and gensets in the output range from kWel to 4,500 kWel. In this way, we can set up power plants with an output of 100,000 kWel and more. The gas engines can be operated with various types of gas, such as natural gas, shale gas, mine gas, biogas, landfill gas, sewage gas, and syngas. They are designed for maximum electrical and thermal efficiency, low operating and service costs, and high reliability and availability. Thus, they reach efficiency levels of more than 90 percent.

Methane Slip Causes Emissions that Are Harmful to the Environment

Methane emissions from cogeneration power plants are a known problem in the field of sustainable heat and power generation. During the cogeneration process, the fuel gas is not fully burned in the combustion engine of the cogeneration power plant. As a result of the so-called methane slip, valuable energy remains unused, and methane enters the atmosphere as greenhouse gas. In view of the approximately 8,000 biogas plants in use in Germany alone, this can cause a considerable negative increase of the greenhouse effect.

Caterpillar Energy Solutions Expertise Is Valuable to the Research Project

The REMISBIO project engages in valuable research work in order to minimize the above-mentioned effect. For this purpose, innovative catalyst materials are manufactured and tested for effectiveness and stability. In this area, Caterpillar Energy Solutions – which, through its MWM brand, is one of the most experienced manufacturers of eco-friendly combined heat and power plants with cogeneration for distributed economic, energy-efficient power supply – can support the team with its long-standing experience in the production and further development of powerful gas engines.

Caterpillar Energy Solutions contributes its extensive test setup and performance knowledge to the research project and makes customer facilities such as the biogas plant Karsdorf available for test purposes. The REMISBIO project also benefits from the wealth of experience of Marcus Dürrschmidt of the Plant Technology team with respect to the exhaust emission measurement and recording of the performance data of the newly developed catalysts.

Mobile Test System Ensures Real Exhaust Conditions

To conduct tests under real conditions, the catalysts developed in the project are installed in industrial plants. However, to make sure that the cogeneration power plant operation is not disrupted by the ongoing installation and removal of the catalysts, the research team has come up with a special solution: An external, mobile plant has been developed that merely needs to be connected once to the exhaust system of the cogeneration power plant. Thereafter, the catalyst samples to be tested can easily be replaced without interrupting the CHP plant operation.

Emission measurement on the container of the Karsdorf biogas plant of Dresdner Vorgebirgs Agrar AG by the experts Marcus Dürrschmidt (of Caterpillar Energy Solutions), Rene Bindig, and Sebastian Günter (both of DBFZ, from left to right)

Emission measurement on the container of the Karsdorf biogas plant of Dresdner Vorgebirgs Agrar AG by the experts Marcus Dürrschmidt (of Caterpillar Energy Solutions), Rene Bindig, and Sebastian Günter (both of DBFZ, from left to right)

REMISBIO Nominated as the First Project for the Environment Show

The REMISBIO project is funded by the Federal Ministry for Economic Affairs and Energy (BMWi) under the “Biogas energy use” program. The entire funding program has existed since 2008 and now comprises 99 joint projects and 247 individual projects that have already been provided with about €48 million. However, REMISBIO is the first project to be nominated for the “Environment Week”. The renowned event showcases a total of about 200 projects from Germany and Switzerland on the subjects of climate protection, energy, resources, etc.

Further Information:

Photos: DBFZ

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 621 48 18 35 76

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 621 48 18 35 16

E mwm-press@cat.com