TEDOM and MWM Service Complete E70 General Overhaul of Two MWM TCG 2032 V16 Gas Engines at Record Speed

Schwaz, May 25, 2022

Close to perfection: After intensive preparation and a highly organized process that started with the order placement in Austria, the construction of the exchange engine blocks in Spain, and the delivery of spare parts from Germany, the coordination of the work steps and tasks with the teams from the Czech Republic, and finally the delivery and assembly in Slovakia, everyone’s goal has been achieved—two MWM TCG 2032 V16 gas engines have been overhauled at the same time, and with the shortest possible downtime.

The power plant that has been in operation in Bratislava since 2012 generates an electrical output of 8.6 MW and supplies its energy to the local grid. During this time, the two units generated over 1.2 billion kWh of electrical energy over a period of 150,000 operating hours. The thermal energy that can be used through cogeneration is fed directly into Bratislava’s municipal district heating network. It was therefore very important that the E70 general overhaul—which was necessary after 10 years of continuous operation and was carried out during the heating period—would be completed quickly and smoothly. In order to carry out this challenging task, the plant operator relied on the long-term proven cooperation with TEDOM, which specializes in combined heat and power (CHP) plants and operates worldwide, as well as on the expertise of MWM Austria GmbH, whose teams had already been involved in the planning and construction of this plant.

Five Countries, One Goal: Exemplary Cooperation Enables General Overhaul in Just 15 Working Days

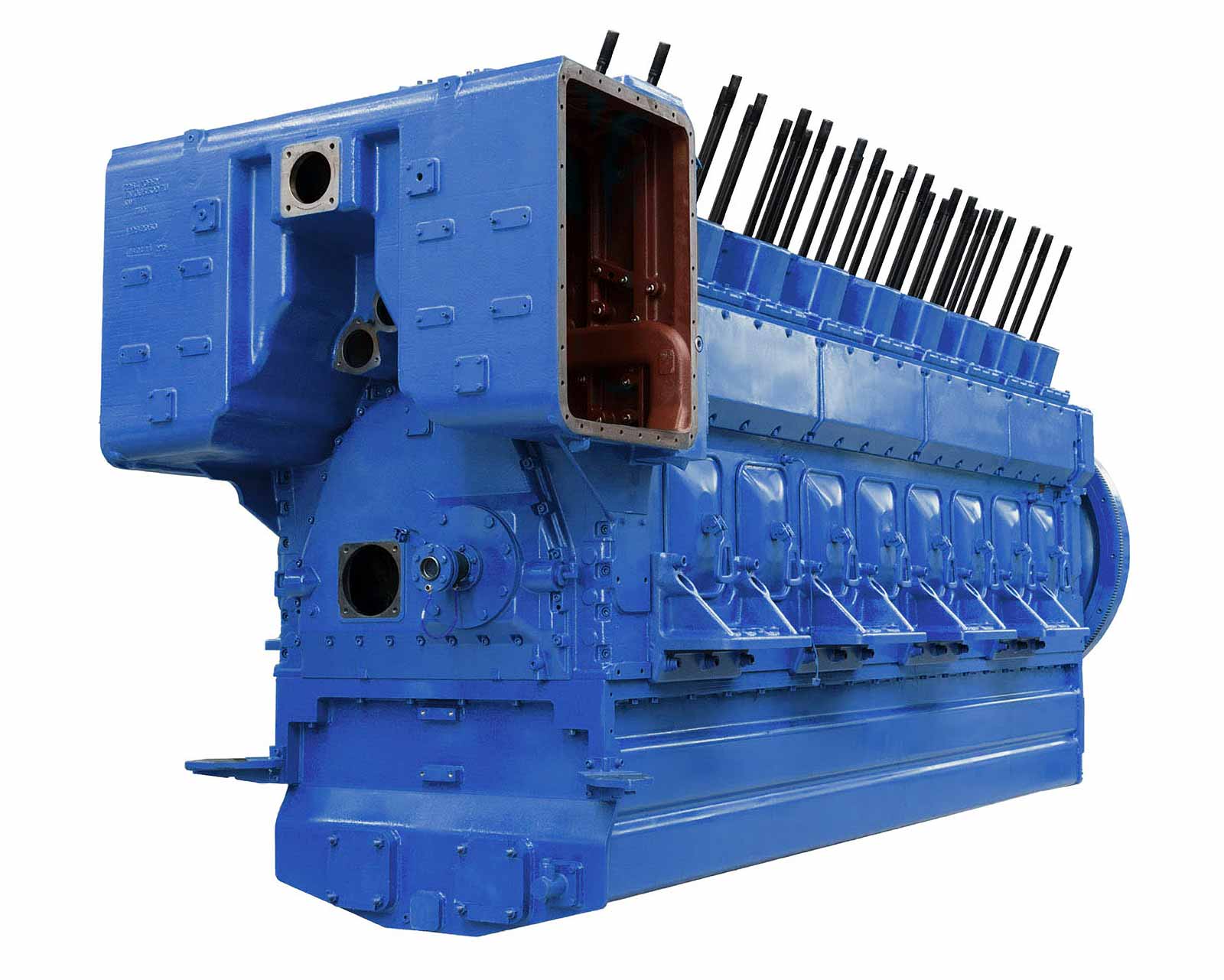

To carry out the overhaul of the two units as quickly as possible, the parties agreed to use exchange engine blocks from the MWM X-Change program. The TCG 2032 series exchange blocks required for this purpose were reconditioned and delivered by the X-Change Center in Vigo, Spain. In order to meet the customer’s request for the fastest possible overhaul, the plant in Vigo prepared two extended long blocks—a special variant that, in addition to the cylinder heads, also includes the pre-assembled intercoolers.

On February 14, 2022, the time had come. Two trucks delivered the engine blocks, which had previously been prepared in Spain and weighed over 20 t, on schedule. In the meantime, additionally required spare parts and tools were delivered by the MWM worldwide spare parts logistics center in Lorsch, Germany. On the morning of the following day, the two TEDOM service teams started with the conversion work. First, the two gas engines, which, aligned with the generator, weigh approximately 50 t, were pulled out of the engine room on heavy-duty casters. Subsequently, the engine blocks were replaced. By the end of the same day, both units and the overhauled engine blocks had been returned to their original places in the engine room. After that, the detailed work began. TEDOM provided a separate team for each gas engine so that all further work could be carried out at the same time. More work was done on the following days. For example, reusable parts such as the rocker arms and push rods were dismantled from the old engine blocks, inspected, and then reinstalled on the new ones. In addition, generator maintenance was carried out, and the gas control system was renewed.

After only 15 working days, the job was finished. Thanks to the well-coordinated assignment and the exemplary cooperation of all teams, the plant was recommissioned after only 120 working hours under the supervision of a commissioning technician from MWM Austria and was completed on the following days to the full satisfaction of the customer. This means a reduction of 83 percent of the downtime usually incurred for the task without using an exchange engine block. “Despite the complexity and scale of the operation, the exemplary cooperation with the teams from different locations in Europe made it possible to complete this general overhaul in the shortest time possible”, says Noemí Arroyo, Service Team Leader at MWM Austria GmbH.

MWM X-Change Center: Exchange Engines and Exchange Parts for MWM Customers

MWM has been successfully implementing this more economical, more eco-friendly, and faster alternative for its major overhauls for years with its X-Change Centers in Duisburg, Germany, for the TCG series up to 2.3 MW and in Vigo, Spain, for the TCG 2032 series. Used engine blocks are reconditioned at the respective X-Change Centers and brought to an as-good-as-new condition. The customer, in turn, receives a pre-overhauled engine block and does not have to wait for his blocks to be reconditioned. The exchange blocks can be offered in different versions and scopes, such as the basic short block variant, the long block that includes pre-assembled cylinder heads, the extended long block with pre-assembled intercooler, as well as the exchange of the complete engine. In addition, X-Change parts can also be offered individually, e.g. cylinder heads, intercoolers, starters, etc. And best of all: All X-Change engine blocks and X-Change parts come with a manufacturer warranty for 12 months after commissioning.

Further information:

- MWM X-Change

- Website TEDOM a.s.

- Video MWM X-Change Center Vigo, Spain *

- MWM TCG 2032 Gas Engine

- MWM Gas engines and Generator Sets

- MWM Distributed Power Plants

* By clicking the link specified above, you will leave the MWM website and access the external website of another provider (Google Ireland Limited). On this website, this provider’s privacy policy applies, and cookies may be set by this provider. We do not have any influence on this.

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 621 48 18 35 76

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 621 48 18 35 16

E mwm-press@cat.com