“Cogeneration Power Plant of the Month” of March: Dairy Business Makes Use of Trigeneration with Cogeneration Power Plant and MWM Gas Engine for Climate-Friendly, Energy-Efficient Production of Dairy Products

Mannheim, April 22, 2021

Andechser Molkerei Scheitz GmbH, based south of Munich, Germany, produces dairy products such as curd, butter, and cheese from the milk supplied by organic farms. For this, the company needs energy as well as heat, cold, and compressed air for heating the milk in the production process. To ensure sustainable energy management and preheating of the products, internal heat sources are made use of. Apart from an MWM gas engine, a compressed air cogeneration power plant and an absorption chiller are used to supply the dairy operation with energy, heat, and cold. “Energie & Management” magazine has designated the cogeneration power plant with the the MWM gas engine as “Cogeneration Power Plant of the Month” of March 2021.

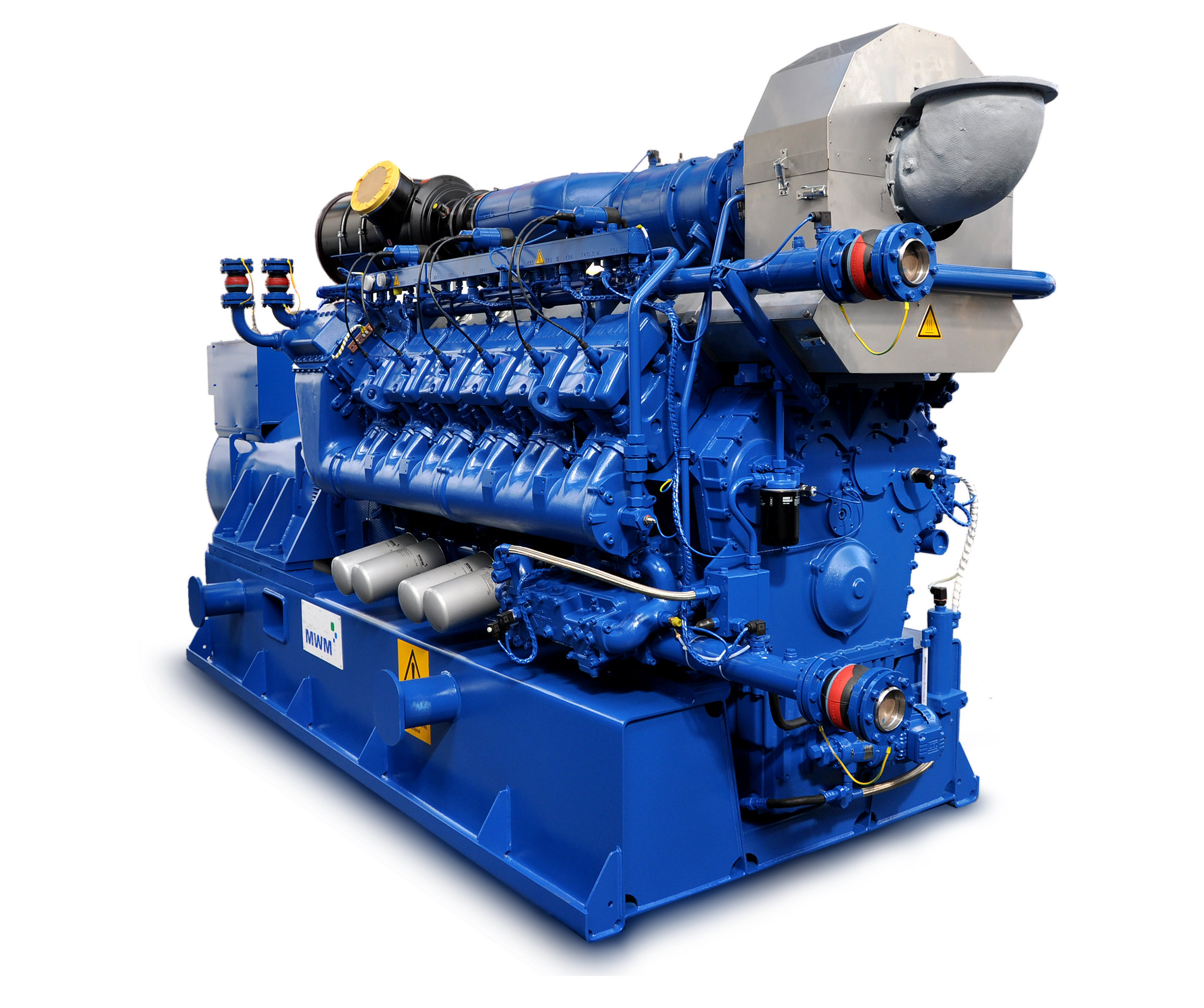

Gas Engine Exhaust Heat Used to Produce Hot Water

The cogeneration power plant consists of a natural gas-fueled MWM TCG 2020 V12 gas engine with a boiler output of 2,380 kW. The connected generator delivers 999 kW of electrical energy. For the steam generation, the exhaust gas from the gas engine is cooled down from a temperature of 413°C to 190°C. Before the exhaust gas enters the boiler, it is treated in an oxidation catalyst. The exhaust heat from the engine produces hot water, which is post-heated by means of an exhaust heat exchanger. The absorption chiller generates about 431 kW of cold.

Primary Energy Savings of up to 30 Percent, Carbon Emissions Down 1.6 Million kg/Year with Cogeneration Power Plant for Distributed Energy Generation

To ensure power-controlled operation of the cogeneration power plant, the trigeneration plant is included in the controls of the boiler and chiller systems as base load capacity. Thus, the system is able to run under full load for at least 7,500 hours/year. “As we will additionally use the energy of the mixture cooler—which is normally lost—at a temperature of 60°C for our hot water generation, the plant’s total efficiency rises to 91 percent”, explains Josef Scheuermeyer of the Energy, Environment, and Sustainability Management of Andechser Molkerei Scheitz GmbH. In combination with the absorption chiller, the cogeneration power plant saves 30 percent of primary energy and up to 1.6 million kg of carbon a year and cuts the dairy company’s power and fuel costs.

Optimized Energy Management with Cogeneration and Trigeneration

Compared to the separate generation of electrical energy and heat, cogeneration and trigeneration plants make much better use of the primary energy. MWM cogeneration power plants enable economically and ecologically efficient energy generation. The plant transforms the utilized energy into electrical energy and heat right on site. The resulting exhaust heat can be reused directly and is not lost. Viable fuels include natural gas, biogas, waste gas, or other gases. The power generated by the cogeneration power plants can be consumed on site or be fed into the public grid for a feed-in tariff.

Reference sheet Andechser Molkerei

Click this brochure to access the digital publishing platform issuu.com. This website is governed by the issuu Privacy Policy.

All languages on issuu: EN | DE

Download PDF: EN | DE

Further information:

- MWM TCG 2020 V12 Gas Engine

- MWM Gas Engines and Power Gensets

- MWM Cogeneration Power Plants

- Energie & Management: “BHKW, Absorptionskälteanlage und Druckluft” (in German)

- MWM press release: MWM Flex Cogeneration Power Plant for Biogas Plant in Lower Saxony Designated “Cogeneration Power Plant of the Month” of January

- MWM press release: Modernized MWM Cogeneration Power Plants for Ecological Botanical Garden of University of Bayreuth Designated as “Cogeneration Power Plant of the Month” of February

- MWM press release: Highly Efficient, Eco-Friendly Trigeneration Power Plant at La Unión: MWM TCG 2020 V16 Gas Engine Produces Power and Cooling Energy at One of Spain’s Largest Fruit and Vegetable Producers

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 621 48 18 35 76

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 621 48 18 35 16

E mwm-press@cat.com