CHP Plant with MWM TCG 2016 V16 Gas Engine in Chocolate Factory Honored as Highly Sustainable Energy Concept

Mannheim, May 29, 2019

For the second time in a row, “Energie & Management” magazine has designated a project involving the use of an MWM gas engine as “Cogeneration Power Plant of the Month” in recognition of a highly sustainable energy project. The SES-HPC 800 N cogeneration power plant with the MWM TCG 2016 V16 gas engine was installed by the MWM service partner and cogeneration power plant manufacturer SES Energiesysteme GmbH. Thanks to the joint project of MWM, SES Energiesysteme, and the planner GWE Wärme- und Energietechnik, the chocolate manufacturer Weinrich is now able to cover a large portion of its power demand from its internal production. The new plant went live in the fall of 2018.

MWM Engine Supports Efficient, Continuous Power Supply of the Factory

To handle the chocolate production of about 22,500 t/year, the chocolate manufacturer Weinrich decided to establish a new energy center for the factory. For this, the chocolate factory’s about 45-year-old steam boiler and decentralized cooling system were replaced with a new SES cogeneration power plant including a natural-gas-fired MWM TCG 2016 V16 gas engine with an output of 800 kWel. The factory’s new energy center bundles the generation of power, hot water, warm water, and cold water in a trigeneration plant. As a result of the modernization, the chocolate manufacturer is now able to cover two thirds of its power demand from its internal production with the MWM gas engine and the new cogeneration plant.

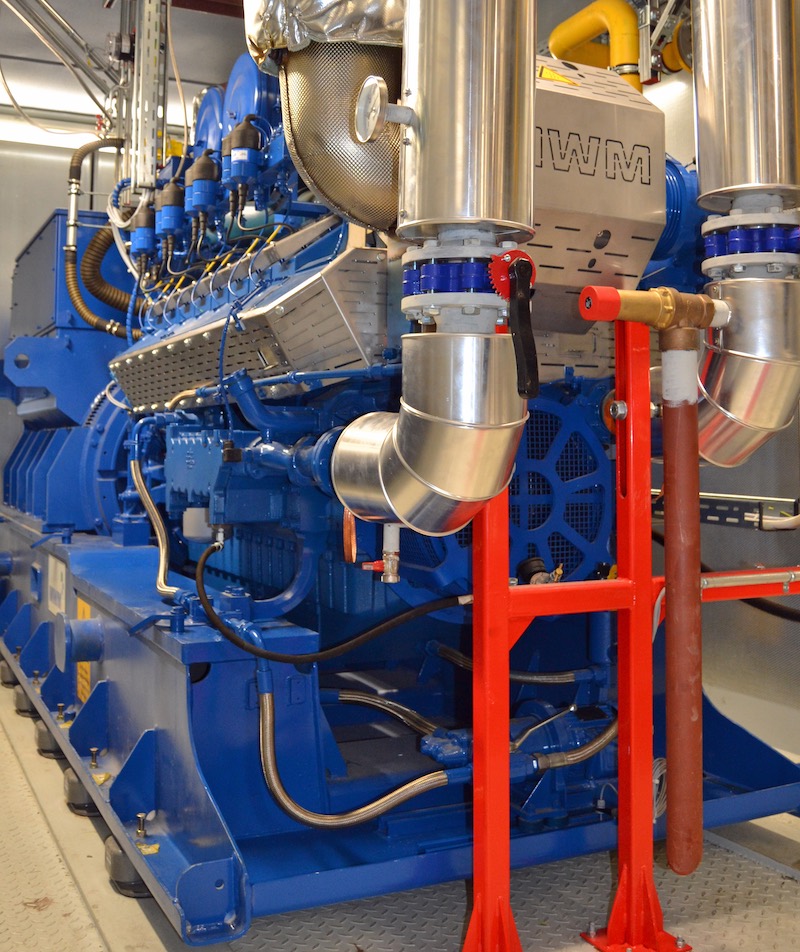

With its MWM TCG 2016 V16 gas engine in the output range of 800 kWel, the cogeneration power plant from SES Energiesysteme enables efficient, eco-friendly power production. (Photo: Ludwig Weinrich GmbH & Co. KG)

With its MWM TCG 2016 V16 gas engine in the output range of 800 kWel, the cogeneration power plant from SES Energiesysteme enables efficient, eco-friendly power production. (Photo: Ludwig Weinrich GmbH & Co. KG)

Reduced Energy Costs and Carbon Savings

By switching to the energy-efficient, eco-friendly production, the chocolate manufacturer saves both energy costs as well as up to 1,950 t of carbon a year. Another special feature of the plant: three hot, warm, and cold water storage tanks that can be flexibly filled and emptied depending on the production needs and the time of the year.

For its ecologically responsible energy concept, the chocolate manufacturer’s project was presented as “Best Practice Example” at the B.KWK conference 2018.

Aerial view of the Weinrich chocolate factory in Herford (Photo: Ludwig Weinrich GmbH & Co. KG)

Aerial view of the Weinrich chocolate factory in Herford (Photo: Ludwig Weinrich GmbH & Co. KG)

In November 2018, we had already reported about the new cogeneration power plant of the Weinrich chocolate factory. The press release with further information on the MWM gas engine and on the project of SES Energiesysteme in general is available here.

Further information:

- Energie & Management, April 2019: “Intelligente Wärme-Kombination für Schokoladenfabrik” (PDF, in German)

- MWM press release: New Energy Center for Weinrich Chocolate Factory: MWM Partner SES Energiesysteme Installs New Cogeneration Power Plant for Trigeneration

- MWM Gas Engines and Power Gensets

- MWM Cogeneration Power Plant Solutions

- Website of the Weinrich Chocolate Factory

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 621 48 18 35 76

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 621 48 18 35 16

E mwm-press@cat.com