CHP Plant with MWM Gas Engine Again Designated Cogeneration Plant of the Month: TCG 2016 Supplies Energy to frischli Milchwerke

Mannheim, October 26, 2017

For about a year, frischli Milchwerke, manufacturer of a wide range of milk products since the 1960s, has been producing power and heat energy in its own distributed cogeneration power plant. The decision to install a CHP plant for independent energy generation was made particularly under consideration of economic benefits.

The concept for the new energy supply, the general planning, and the project management were handled directly by frischli Milchwerke GmbH. The objective was to install a flexible system that would ensure independence from the public power grid and from the steam boilers previously used for heat generation at the headquarters in Rehburg-Loccum near Hannover, Germany. In collaboration with MWM partner SES Energiesysteme, this ambitious goal was reached when the cogeneration power plant went live in mid-2016. The project has been so successful that the energy center, which is based on a CHP (combined heat and power) plant, was designated as “Cogeneration Plant of the Month” in August 2017 by the industry magazine “Energie & Management”.

On two levels, the energy center hosts the cogeneration power plant, the turbines, and the boiler. (Photo: frischli Milchwerke GmbH)

A Lot of Power for a Lot of Milk: MWM TCG 2016 Gas Engine Delivers Energy for Processing 785,000 t of Milk/Year

The cogeneration plant delivers an electrical output of 600 kWel and a thermal output of 658 kWth. An MWM TCG 2016 gas engine constitutes the core of the cogeneration plant. The thermal energy is used entirely by the new milk powder drying tower on site. Due to the parallel operation of the CHP plant and the milk powder production in the drying tower, the genset can pre-heat the drying air. The cogeneration plant can be switched online or offline whenever needed, as the 20-m3 heat storage unit serves as a buffer. In the event of excess power, the cogeneration plant can thus be switched off without disrupting the dry tower operation, as thermal energy can continue to be extracted from the heat storage unit.

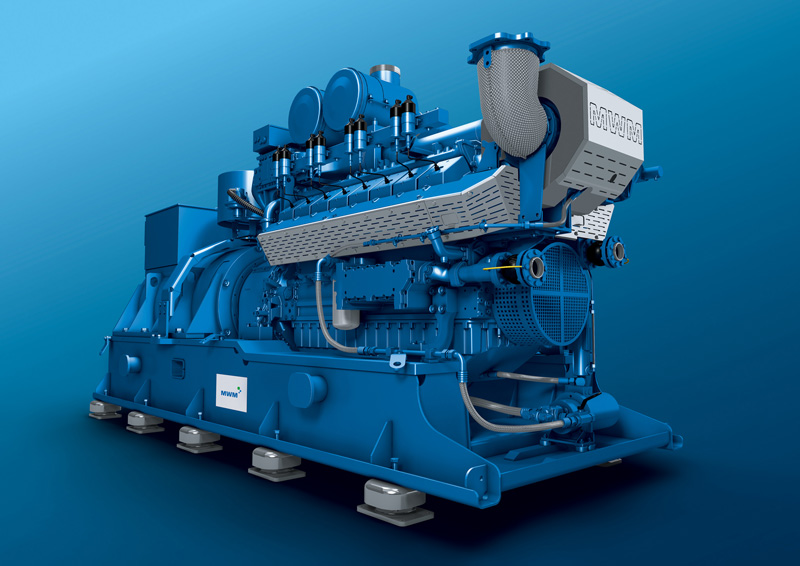

An MWM TCG 2016 gas engine constitutes the core of the cogeneration plant.

An MWM TCG 2016 gas engine constitutes the core of the cogeneration plant.Maximum Flexibility, Optimum Energy Security: Gas Turbines and Emergency Diesel Genset Enable Flexible Energy Generation

The second key component in the energy center of frischli Milchwerke is a micro gas turbine plant with exhaust heat boiler. This unit supports the power generation with en electrical output of 800 kW and heat production via the exhaust heat boiler with additional fire for up to 10 t of steam an hour. A heat storage unit as in the MWM cogeneration plant is not required, as the electrical output of the turbines can be controlled independently of the exhaust heat boiler, enabling flexible use of the electrical output.

Additionally, an emergency diesel genset with an output of 660 kVA is available in order to ensure continued distributed power generation even in the event of maintenance work or malfunction of the cogeneration power plant. The current positive or negative output can be read and controlled at all times via the data to connection to a modern plant control. In fact, the plant’s flexibility and wide range of options were the main reasons for its designation as cogeneration plant of the month.

Further Information:

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 621 48 18 35 76

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 621 48 18 35 16

E mwm-press@cat.com