Amul Dairy: MWM TBG 620 V16K Gas Engine Ensures 100-Percent Capacity Utilization and Uninterrupted Dairy Operations

Mannheim, September 16, 2021

Kaira District Co-operative Milk Producers’ Union Limited, popularly known as “Amul Dairy” is a farmers’ cooperative established in 1946 in Anand, India. It has a membership of 3.6 million farmers and is the largest dairy brand of India. Currently, Amul is world’s ninth-largest dairy organization. The trigeneration system has been in operation for 15 years. The cooling energy is used for the pasteurization of the milk. The dairy products manufactured in this plant are marketed throughout India and also exported to other countries globally.

High Engine Output for High Production Demands

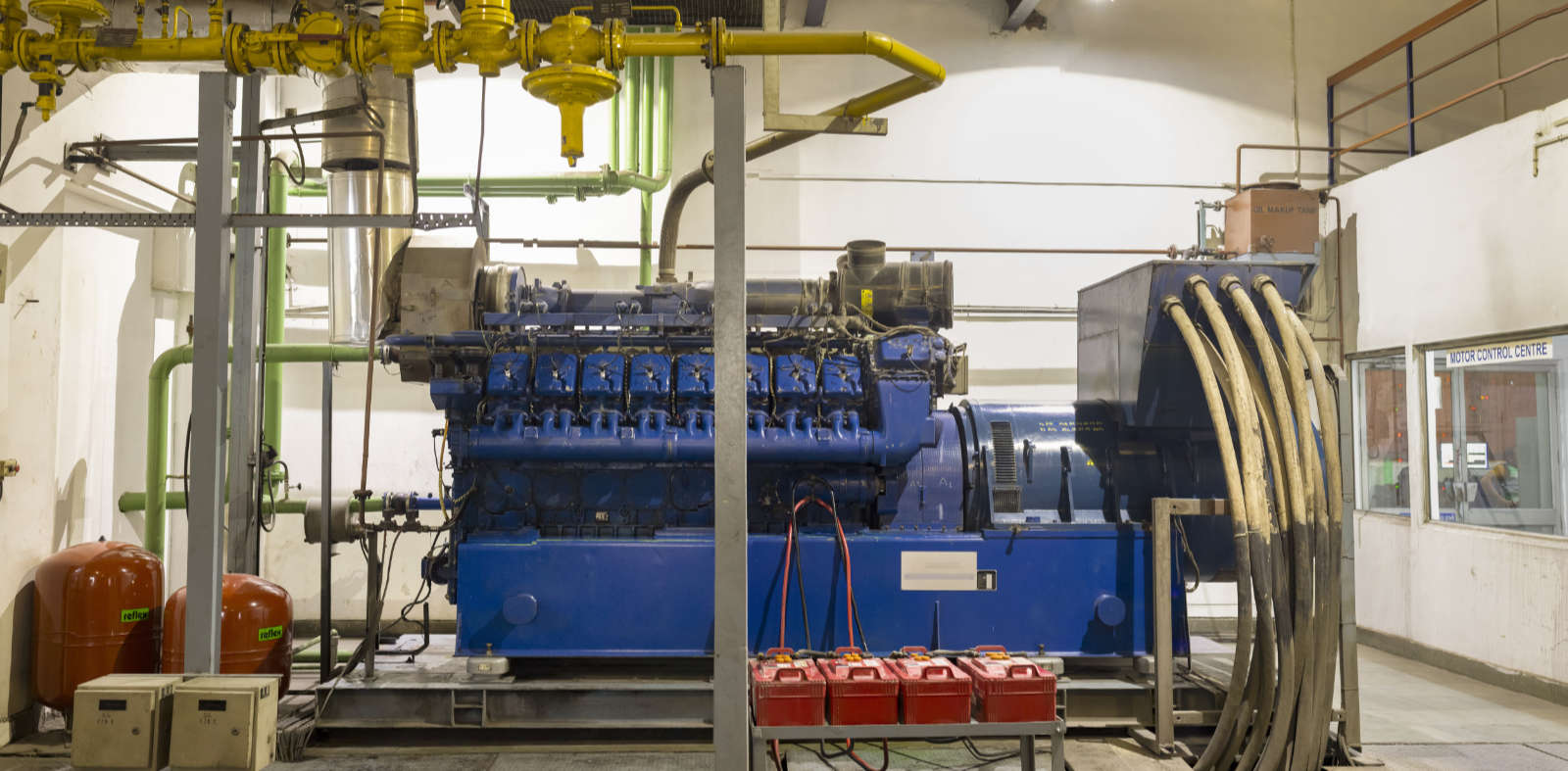

The MWM TBG 620 V16K gas engine, which has an output of 1,364 kWel, was installed by the Indian MWM distributor Green Power International (Private) Ltd. This year, the fourth gas engine in Green Power’s genset portfolio, which operates on the premises of Amul Dairy, completed 100,000 operating hours.

Thanks to the reliability of the genset and the assistance of Green Power’s service team, the facilities operated at a utilization level of 100 percent throughout the COVID-19 lockdown period. Thus, Amul Dairy was able to continuously supply essential dairy products to the entire nation.

The MWM TBG 620 V16K gas engine—the predecessor of the MWM TCG 2020 V16 K gas engine—was installed along with a vapor absorption machine (VAM). The VAM stands close the CHP unit, which supplies it with heat. The VAM works on the basis of a thermal compressor and consists of an evaporator, condenser, generator, and absorber. The evaporator sprays and evaporates the water, producing cold. The humidity is absorbed by salt, and steam from the air is captured in the absorber. In the generator, water is extracted from the saline solution. The regenerated saline solution goes back to the absorber, and the condenser cools the generated steam to the original temperature and condenses it.

Trigeneration for Milk Processing and Cooling

Amul Dairy uses the cold produced via cogeneration for the pasteurization of the milk and the production of dairy products. Every day, the business pasteurizes some 5 million liters of milk and processes it for use in food products.

Trigeneration solutions with vapor absorption machines enable optimum cold storage of products. Compared to the separate generation of electrical energy and heat, cogeneration and trigeneration plants make much better use of the primary energy. MWM CHP plants enable economically and ecologically efficient energy generation. The plant transforms the utilized energy into electrical energy and heat right on site. The resulting exhaust heat can be reused directly and is not lost. Viable fuels include natural gas, biogas, mine gas, or other gases.

MWM TCG 2020 Gas Engines Deliver High Efficiency

The MWM TCG 2020 gas engines, whose output ranges from 1,000 to 2,000 kWel, are custom-tailored to the challenges of a dynamic market setting. The engines fulfill the elevated requirements of a broad application spectrum and ensure efficiency, reliability, flexibility, environmental compatibility, low TCO, and high profitability. This makes the gas engines especially attractive for industrial CHP plants.

Further Information:

- MWM TCG 2020 Gas Engine

- MWM Gas Engines & Gensets

- MWM Cogeneration Power Plants

- MWM press release: Highly Efficient, Eco-Friendly Trigeneration Power Plant at La Unión: MWM TCG 2020 V16 Gas Engine Produces Power and Cooling Energy at One of Spain’s Largest Fruit and Vegetable Producers

- MWM press release: Trigeneration in the City of London

- MWM press release: New Energy Center for Weinrich Chocolate Factory: MWM Partner SES Energiesysteme Installs New Cogeneration Power Plant for Trigeneration

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 621 48 18 35 76

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 621 48 18 35 16

E mwm-press@cat.com