97 Percent Availability: Biogas-Fueled MWM TCG 3016 Engines Supply Energy to Alb-Danube District

Mannheim, February 23, 2021

BG Biogas Service GmbH operates a biogas plant in the Alb-Danube region in both Langenau and Seligweiler, each with a cogeneration power plant and a satellite cogeneration power plant. Until the engine replacement, all four cogeneration power plants had MWM TCG 2016 gas engines. After some 70,000 operating hours, the oldest cogeneration power plant in Langenau was modernized with an MWM TCG 3016 V16 gas engine in the fall of 2018. About a year later, the gas engine in Seligweiler was also replaced with a new MWM TCG 3016 V16 power genset. The plants are fueled with biogas that is gained exclusively from the digestion of energy plants such as corn and whole plant silage.

Biogas plant and cogeneration power plant at the Langenau site (© Manfred Herrmann). The German city of Langenau to the northeast of Ulm is famous for its many springs. In this water reserve, biogas facilities are required to meet high standards. For example, they are not permitted to use liquid manure.

Higher Income, Lower Operating Costs Thanks to New MWM TCG 3016 Gas Engines

The biogas plants are based at two different locations in Langenau and Seligweiler in order to keep the transport routes of the plant material to the substrate facilities as short as possible. Both facilities are located in close proximity to the areas where the energy plants are grown and are each connected to agricultural businesses. In view of the good experience made with the predecessor model MWM TCG 2016, BG Biogas Service decided to replace the engine with another MWM gas engine for the cogeneration power plant operation. “The high efficiency, reliability, and availability of the gas engine were key criteria that encouraged us to invest in a new MWM gas engine”, explains Hans Michael Keck, Managing Director of BG Biogas Service GmbH. Since the go-live, both gas engines have been running smoothly. Meanwhile, the TCG 3016 V16 gas engine in Langenau has completed some 16,500 operating hours, and the one in Seligweiler about 8,760 hours. “Thanks to the transition to the new MWM engine generation, we earn about €90,000 to €100,000 more every year”, says Keck.

Hans Michael Keck, Managing Director of BG Biogas Service GmbH, in front of the newly installed gas engine (© Manfred Herrmann)

Distributed Energy Generation with Biogas Enables Low Downtimes of Less Than 3 Percent/Year

In late October 2020, the satellite cogeneration power plant in Öllingen was equipped with an MWM TCG 3016 V16 gas engine. The MWM TCG 3016 gas engine was installed by VG Diesel- und Gasmotoren-Service GmbH. The operators of the biogas plants depend on hassle-free operation of the engines, as the biogas-fueled cogeneration power plants do not have any fallback gensets. Thanks to the new engines, the combined heat and power (CHP) plants merely need to be shut down for inspections and oil change; thus, the downtimes of the cogeneration power plants of BG Biogas Service amount to less than 3 percent.

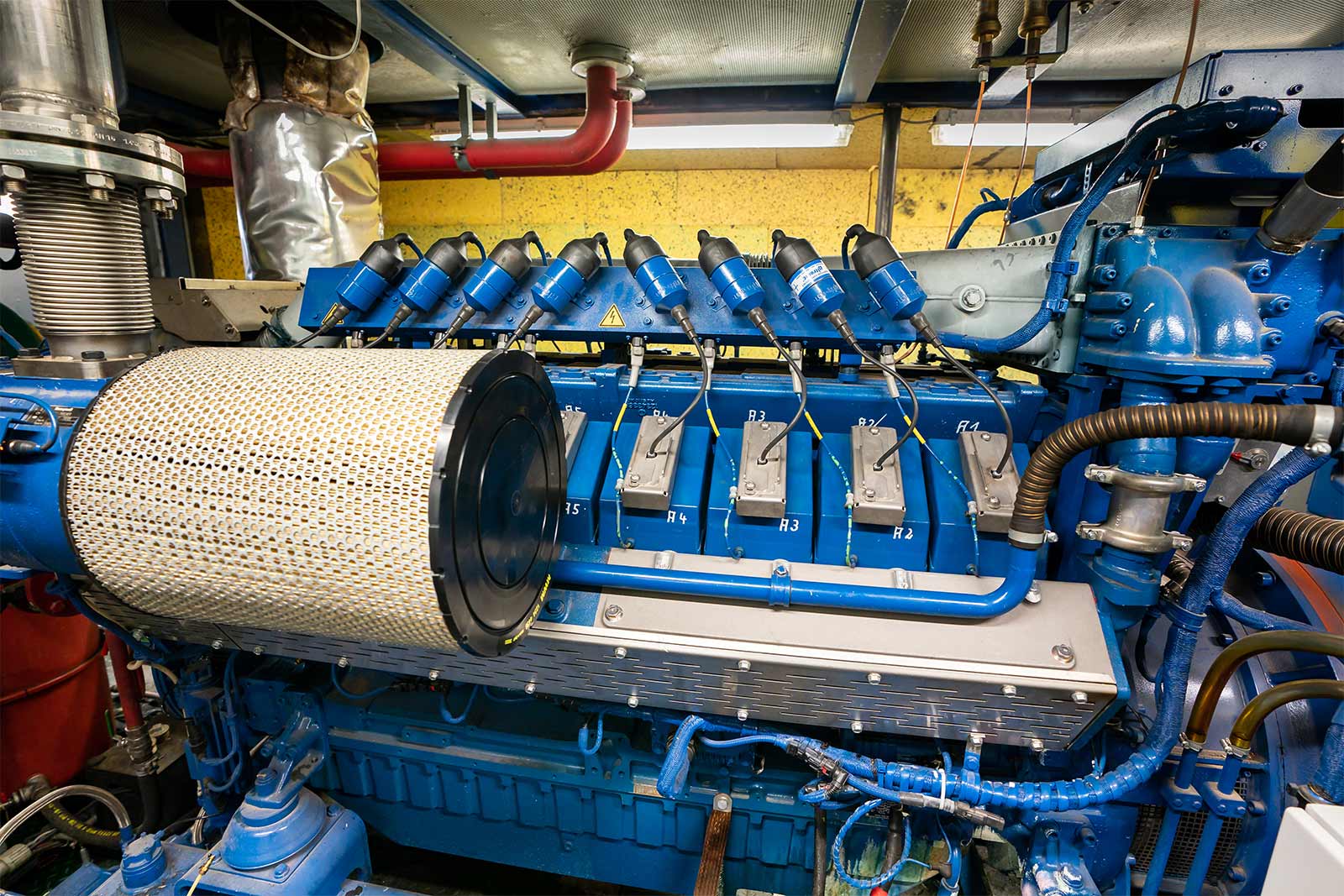

The power gensets run very smoothly and reliably—a precondition for hassle-free operation, as biogas cogeneration power plants usually do not have any fallback gensets. (© Manfred Herrmann)

Biogas Plants and Cogeneration Power Plants Turn Agricultural Operations into Power Producers

The biogas engines in Langenau supply the community with heat and power from cogeneration. The Langenau cogeneration plant has an electrical output of 800 kW and a thermal output of 791 kW. The total efficiency of the cogeneration power plant is 85.7 percent. This form of energy generation from biomass plays an important role in the development of sustainable energy supply. Currently, biogas offers the highest user benefit and the best use of the energy potential of biomass.

MWM offers biogas-optimized gas engines, complete plants, and containers for combined heat and power generation. These systems achieve maximum efficiency in various output segments. MWM also provides the system components required for gas processing and treatment. Where generators are installed in remote areas, the generated energy can even be used exclusively by the plant.

Reference Case CornTec Biogas Langenau and Seligweiler

Click this brochure to access the digital publishing platform issuu.com. This website is governed by the issuu Privacy Policy.

All languages on issuu: EN | DE

Download PDF: EN | DE

Further information:

- MWM Gas Engine TCG 3016

- MWM Gas Engines and Power Gensets

- MWM Cogeneration Power Plants

- MWM Power Plant Solutions for Agricultural Biogas Plants

- Highest Efficiency with MWM Biogas Applications

- MWM Reference Case: CornTec Biogas-Langenau GmbH & Co. KG, CornTec Biogas-Seligweiler GmbH & Co. KG

- MWM press release: MWM CHP Biogas Station for Epirus Waste Processing Plant in Greece: Eco-Friendly Green Power from Neighborhood Waste Supplies National Power Grid

- MWM press release: Sustainable Energy Cycle for Mallorca: MWM Gas Engines Produce Eco-Friendly Energy from Organic Waste

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 621 48 18 35 76

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 621 48 18 35 16

E mwm-press@cat.com