Distributed Power Plant Solutions for Mines

Xishan Coal Mine, Shanxi, China

- Improve mine safety

- Reduce carbon dioxide release into the atmosphere

- Reduce electrical energy costs and generate income

Maximization of Fuel Resources

MWM has developed gas engines and power generators especially for coal-mine methane (CMM). Implementing methods to use this gas as an alternative fuel can help:

- Improve mine safety

- Reduce carbon dioxide release into the atmosphere

- Reduce electrical energy costs and generate income

MWM Supports You in Your Power Plant Projects by Offering:

- Expertise in the development and planning of large projects

- Logistical and technical installation support

- On-site maintenance

Our Gas Engines for Coal-Mine Methane Offer:

- Customized motor controls for managing the constant fluctuations of the methane gas content

- A fuel system that can process gas with the very low pressure typical to mining pit venting systems

Coal Mine Gas – Ecological and Economically Attractive

Coal-mine methane is a by-product of coal formations in subterranean coal seams, and is released before or during active coal mining. Coal mines worldwide emit volumes of methane gas approximately equivalent to 400 million tons (28 billion cubic meters) of carbon dioxide. This corresponds to the consumption of 818 million barrels of oil or carbon dioxide emissions of 64 million passenger vehicles.

Coal mine methane emissions can be significantly decreased through the recovery and utilization of drained gas via methane gas energy projects. The CMM is sequestered and used for fuel in reciprocating gas engine generator sets. This mature and proven technology is highly effective for gas mitigation and power generation. After the recovery of the CMM from the ground, it is stored in large containers and pretreated for use in gas engines. The pretreatment consists of dust and particle filtering, gas drying and transport via pressure-controlled fuel pipelines to the on-site generator sets.

Coal-bed methane (CBM), coal-mine methane (CMM) and abandoned mine methane (AMM), are all suitable for utilization in gas engines due to their high methane content from 30 to 95 percent. Ventilation air methane (VAM) has a CH4 content between 0.2 and 1.5 percent, which is why it is not suitable for power generation in gas engines.

Through the use of coal mine gas with methane concentrations of up to 30 percent, methane, which is harmful to the environment and would otherwise be released into the atmosphere, can be converted into useful energy.

The use of coal mine gas in a gas engine offers two-fold advantages: First of all, methane is converted to carbon dioxide during combustion, which is up to 25 times less harmful to the environment. Second of all, up to 90 percent of the energy bound in the methane can be converted into electricity and heat.

Gas Engines & Products

Cogeneration Power Plant Solutions

Eco-friendly MWM cogeneration power plants with combined heat and power enable decentralized, economical and energy-efficient power production.

Container Cogeneration Plant

Compact modules for the TCG 3016, TCG 3020 and 2020 gas engines. Complete turnkey systems for special applications.

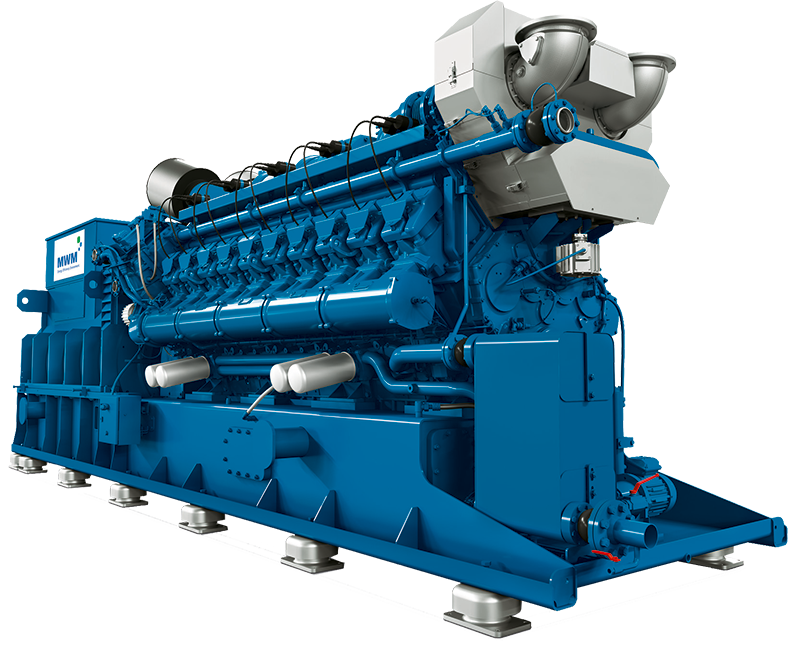

Gas Engine TCG 3020

The All-Round Talent. Smart, secure plant control. Higher output and profitability despite compact design.

Contact Sales

Caterpillar Energy Solutions GmbH Carl-Benz-Strasse 1 68167 Mannheim Germany