Gas and Dirt Separator for Cooling Systems in MWM Gas Engines

Make Your Plant Even More Resilient

- Optimized venting of air and micro gas bubbles compared to conventional vents

- Cleaned coolant for less dirt in the cooling system

- Thanks to the gas and dirt separator, the cooling system does not need to be emptied when cleaning the coolant

- Longer useful life of the main cooling system components

- Better heat transfer

Be on the Safe Side with the MWM Gas and Dirt Separator

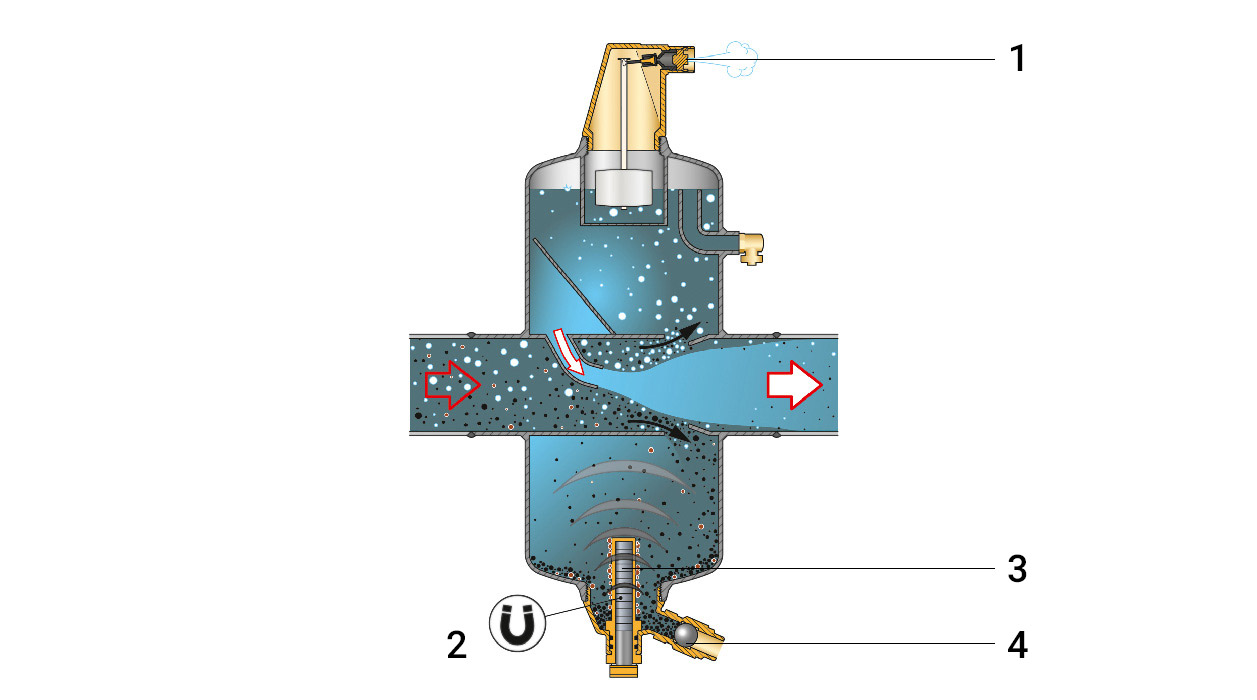

Despite the high standards for technical cleanness, the complex plant cooling system can suffer from harmful micro bubbles and dirt particles. In the event of cavitation, i.e. the sudden dissolution of these micro gas bubbles, the cooling system components can suffer damage. Moreover, dirt in the cooling system can make it more difficult for the plant to operate smoothly. By using the MWM gas and dirt separator, dirt particles and micro bubbles can be eliminated at an early stage, resulting in significantly longer useful life of the plant cooling system and of the other components.

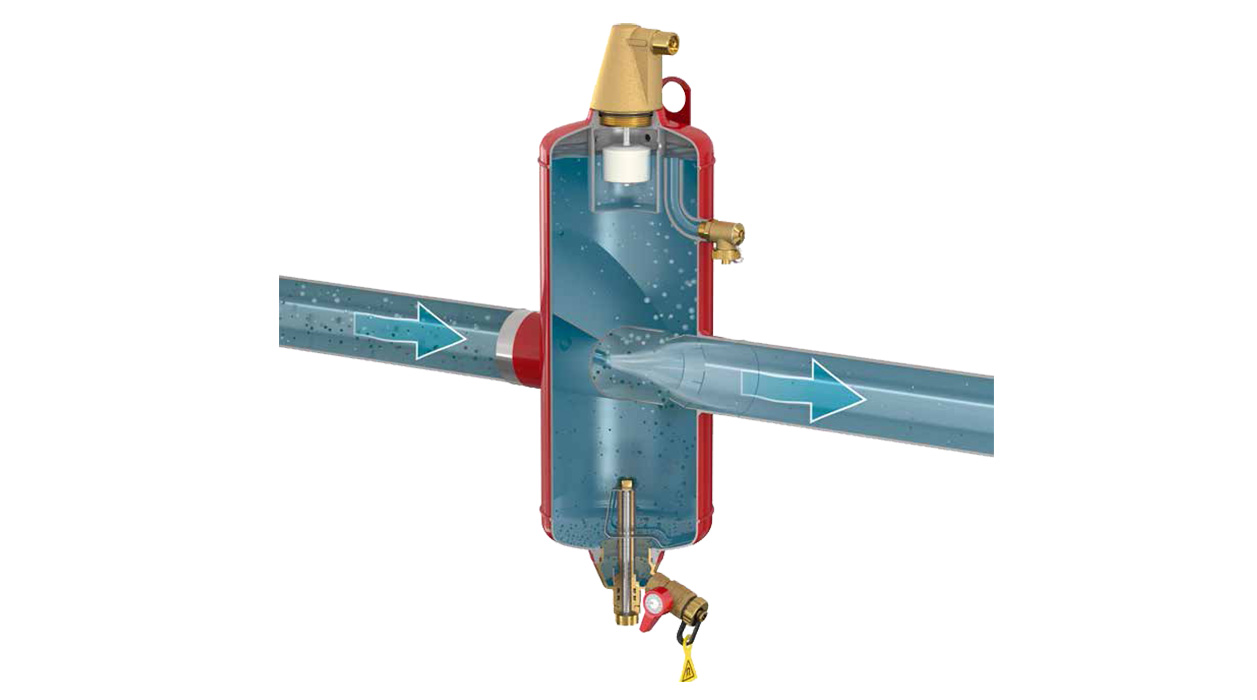

Function of the Gas and Dirt Separator for Gas Engines

Installation and Commissioning of the MWM Gas and Dirt Separator

The size of the gas and dirt separator depends on the volume flow in the engine cooling circuit. To install the gas and dirt separator, the gas engine needs to be stopped briefly. The separator is attached where the system pressure is the lowest, i.e. at the engine outlet on the suction side of the coolant pump. The length of the straight horizontal pipe before the inlet of the separator must be at least 30 cm. The gas and dirt separator is available for all MWM gas engine series. The commissioning is carried out by qualified MWM service personnel.

Contact Service

Caterpillar Energy Solutions GmbH Carl-Benz-Strasse 1 68167 Mannheim Germany

T +49 6 21/3 84 – 0 F +49 6 21/3 84 – 88 00 E service@mwm.net