Energy-Efficient Solution for World’s Third-Largest Tea Manufacturer R. Twining: Modern CHP Plant with MWM Gas Engines in Poland Reliably Supplies Factory with Heat and Power

Mannheim, December 12, 2024

Twinings is the world’s third-largest tea manufacturer and part of the Associated British Foods (ABF) Group. The Twining factory in Swarzędz (R. Twining and Company sp. z o.o.), which started production in 2011, is the largest and fully automated tea factory in Europe, producing more than 500 different blends of this popular beverage.

In 2022, Twinings decided to invest in a combined cooling, heat, and power (CCHP) plant with MWM gas engines for the Swarzędz factory. The decision to install the new CHP plant was made especially to reduce the carbon footprint and save on energy costs. After all, these costs significantly affect the final price of the products offered. Other important reasons for generating energy with CHP technology were to use the energy for the tea production more efficiently, to stabilize the energy supply, and to reduce carbon emissions in the production process.

MWM Generator Sets Reliably Generate Energy for Tea Production

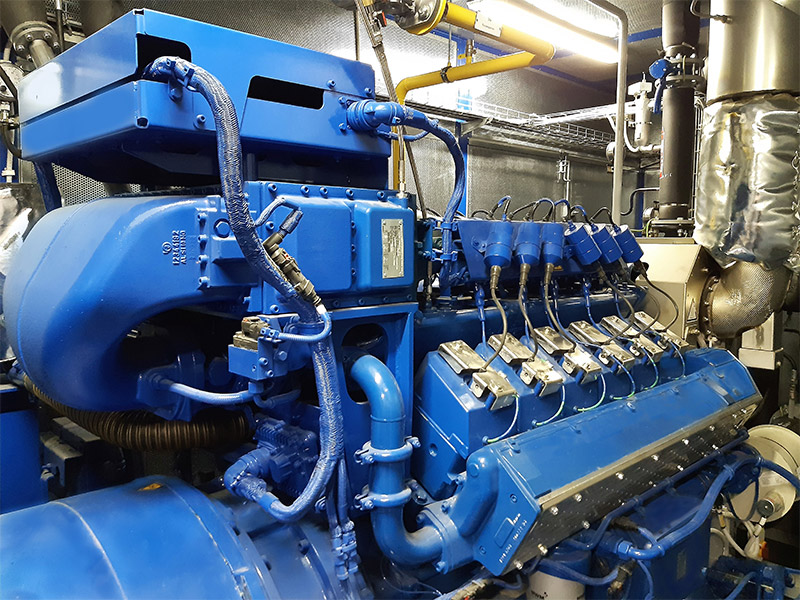

The project was rolled out by Centrum Elektroniki Stosowanej CES Sp. z o.o., the official distributor of MWM in Poland. The trigeneration plant is powered by two MWM gas engines, a TCG 3016 V12 engine with an electrical output of 600 kW and a thermal output of 680 kW and a TCG 3016 V08 engine with an electrical output of 399 kW and a thermal output of 443 kW. In addition to heat and power, the plant also generates cold water using an absorption chiller.

The thermal energy generated in the form of hot water is used for heating in winter and for powering the chiller in summer. The chilled water is channeled into the ventilation system in order to keep the temperature in the production halls at the required level. The entire system is managed using a remote control and visualization system.

Turnkey Implementation of the CHP Plant by Polish MWM Distributor

The MWM distributor Centrum Elektroniki Stosowanej CES Sp. z o.o. implemented the turnkey CHP plant for Twining. The scope of delivery included the planning, the construction of the building for the plant, the delivery of the absorption chiller with cooling tower, the control and visualization system, and the connection to the existing infrastructure.

Reduced Carbon Emissions thanks to Energy-efficient CHP Plant with MWM Engines

The plant for the British tea manufacturer was commissioned in 2023 and has since completed a total of 16,000 operating hours. CES also provides a maintenance service for Twining that includes the CES Cumulus Connect remote monitoring and management service. This enables the operator to interact with the system in real time, check processes, and identify and fix potential problems at an early stage. Thanks to the new CHP plant with MWM gas engines, the British tea manufacturer was able to reduce carbon emissions at its factory in Poland by 2,400 t/year.

Further information:

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 621 48 18 35 76

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 621 48 18 35 16

E mwm-press@cat.com